A New Life for Old Textiles: Our commitment to responsible recycling and brand protection.

Posted on Jul 17, 2025

At CLEAN, doing the right thing shapes how we work. Caring for the environment isn't just a part of our job; we take it seriously every day. We've made steady progress over the years and are making another meaningful change in how we handle textiles that have reached the end of their useful life.

Why We Needed a New Approach

Over time, all uniforms and PPE items, such as gloves, aprons, and hairnets, reach the end of their useful life. We also produce waste such as lint during laundering. In the past, the usual approach was to turn these materials into cleaning rags or send them to landfills.

However, this approach left two important problems unresolved. First, it did not offer the best outcome for the environment. Second, it meant companies lost oversight of what happened to items carrying their logo.

No organisation wants branded workwear to end up in the wrong place, and we recognised it was our responsibility to ensure that did not happen.

Taking a Circular Approach

We're taking a more forward-thinking approach to managing textile waste by moving towards a circular system. Instead of discarding used materials, we focus on ensuring they’re reused, repurposed, or responsibly recycled. This shift reduces our reliance on landfills and helps us lower emissions and make better use of existing resources. We have commenced with recycling workwear, lint, and all waste PPE.

This work also ties in with broader efforts across the industry, like the Textile Services Association’s Infinite Textiles programme, which focuses on improving how textile waste is managed. From 2026, we’ll begin introducing this recycling process to our linen plants, aiming for two sites per year. Taking it step by step means we can stay hands-on throughout, ensuring quality and consistency are maintained as we grow.

Our Recycling Partnership

To help us with this, we’ve partnered with Avena, a UK company specialising in secure textile recycling. We selected them because their SecureBrand? system gives us confidence that branded items will be handled properly. Avena collects the old textiles from our sites, processes them carefully, and prepares the materials for a new purpose. As part of our partnership with Avena, internal PPE waste, such as gloves, aprons, and hairnets, that would typically be sent to landfill will now be recycled through the workwear end-of-life (EOL) collection programme. This initiative supports our commitment to sustainability by reducing landfill waste and lowering associated disposal costs.

They can take a wide range of textiles, from workwear and uniforms to hotel linens and old fabric rolls. Their team knows how to handle different materials, ensuring that anything needing special attention gets it.

The Benefits of the New System

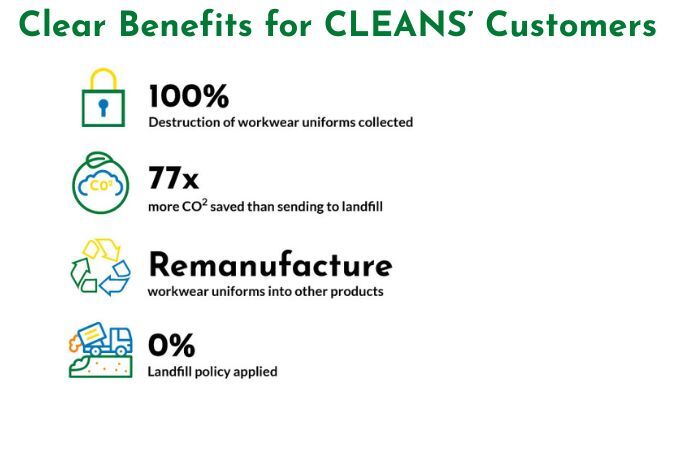

Avena adheres to a strict zero-to-landfill policy. They vet all staff, use GPS-tracked vehicles for collections, and provide detailed records and environmental statements. The end products are durable and valuable, and we receive carbon saving data that meets government standards. These updates help us monitor our actual achievements.

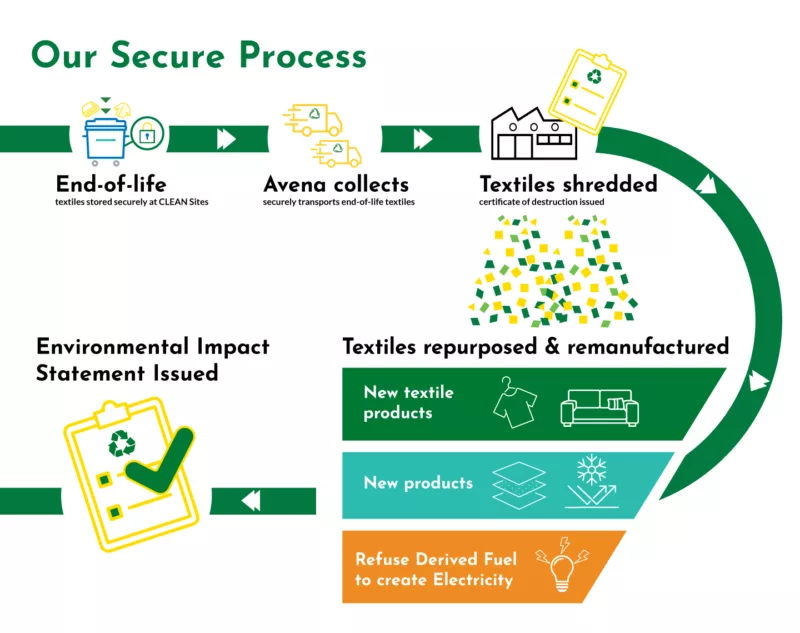

How the Process Works

Textile waste, including workwear, lint, and PPE waste, is collected at our two CLEAN sites before being processed by Avena. Once the materials arrive at Avena, they’re sorted by type and condition. They’re securely shredded before being sent on for recycling. From there, each item follows one of three main paths, depending on what it’s made of and how it can be reused.

Circular Reuse – Back to the Beginning

This is Avena’s first choice and the most sustainable option. After secure processing, textiles are broken down into fibres and turned into new yarns or fabrics. These can then be used to make similar products, like uniforms or linens, keeping materials in circulation.

Advanced Remanufacturing – A New Role

If the textiles can’t be reused in the same way, they’re repurposed into something completely different. Materials are reworked into products like insulation, construction fabrics (geotextiles), and acoustic panels.

Energy Recovery – Making the Most of What’s Left

When textiles are too worn or damaged to be reused or repurposed, energy recovery offers a final option. Using Refuse Derived Fuel (RDF), the energy locked inside these materials is extracted and returned to the grid. It’s not the preferred route, but it ensures that even the most difficult waste still contributes something useful.

At the end of this process, we receive a report showing how much material was recycled, the impact on our carbon footprint, and whether we have met the necessary compliance standards. This lets us see how our old textiles are managed and helps us stay accountable.

Where We Stand Today

From the start of July, we began recycling 25 tonnes of end-of-life textiles per year through Avena. This is the first step. We aim to increase that to 250–300 tonnes annually, covering an even wider range of items, from workwear to other forms of textile waste.

Phased Rollout

We’re starting this initiative at our Cheltenham and Banbury sites, focusing initially on recycling streams such as workwear, lint, and waste PPE. From 2026, we plan to expand the programme to our linen plants, introducing the process at around two sites per year.

By rolling it out gradually, we can ensure each stage is carefully managed, maintaining high quality and oversight standards. This approach allows us to scale responsibly while delivering a reliable and consistent service to our customers as the programme grows.

What This Means for You

Thanks to these changes, we have better oversight of managing textile waste. We can measure our progress, see the environmental benefits, and demonstrate progress towards our sustainability goals. The reports we receive also help us provide clear, meaningful results for the Infinite Textiles Scheme.

We understand the responsibility our customers place in us to protect their brand, reduce environmental impact, and operate with transparency. CLEAN’s service is built to support your ESG goals, offering clear reporting and full audit trails. You remain at the heart of everything we do. Our commitment to consistency, effort, and collaboration ensures dependable results, giving your teams the confidence to focus on what they do best.

Working together reduces risk, lessens environmental impact, and keeps your brand secure. CLEAN is determined to be a dependable partner in your supply chain, supporting your goals while helping more textiles find a responsible new life.

We're pleased to make this change. It's another way we care for our customers, support local communities, and do our part for the planet.

Share this page:

Share